The Significance of Capacitors in HVAC Systems

A/C Capacitors play a crucial role in ensuring the smooth operation of various components. These small yet essential devices are responsible for storing and releasing electrical energy, powering the motors that drive fans and compressors. This article delves into the intricate world of HVAC capacitors, explaining what they are, how they function, why they fail, and methods to prevent their failure.

What is an HVAC Capacitor?

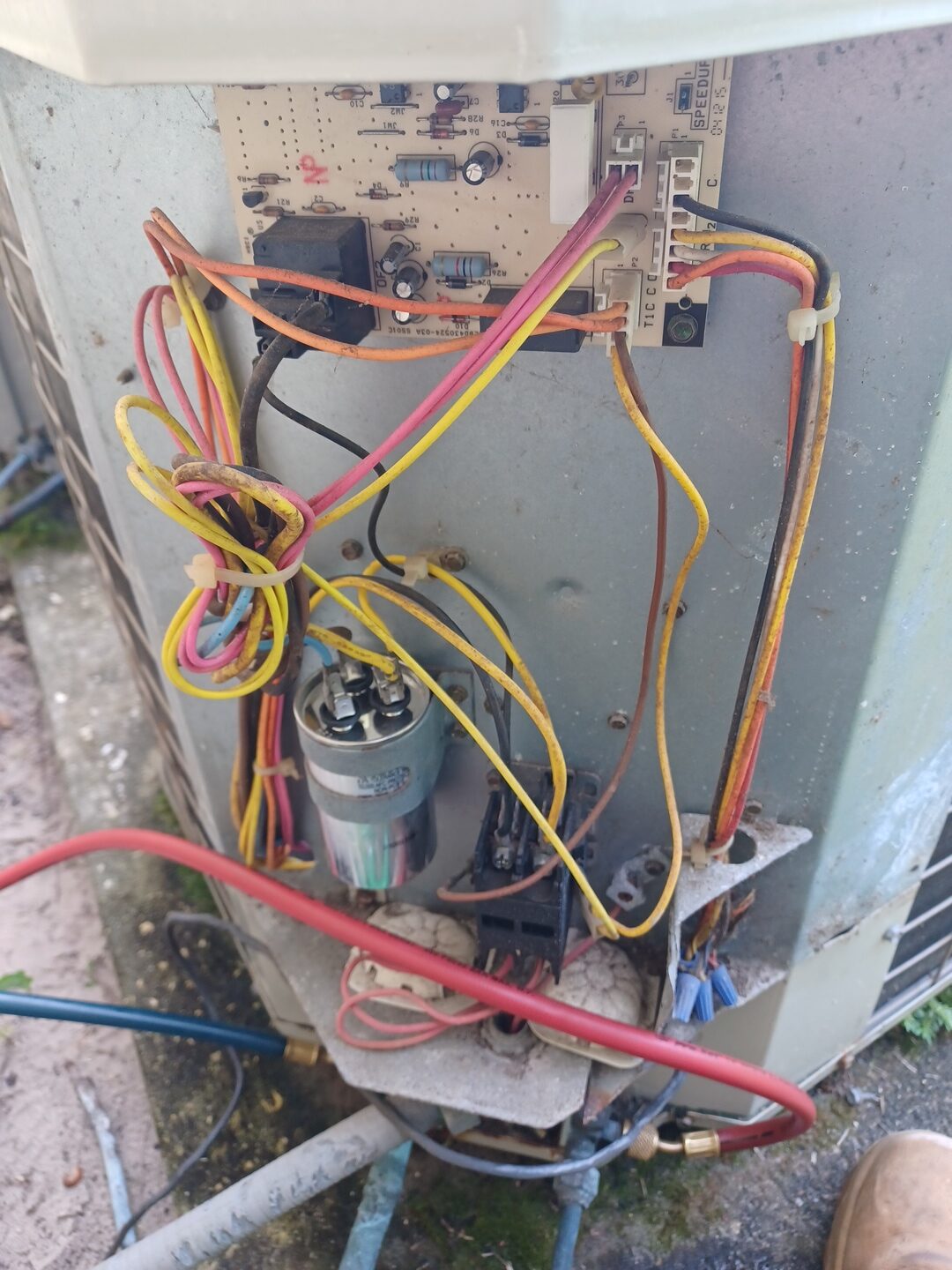

An HVAC capacitor is an electronic component that stores and releases electrical energy in an HVAC system. It is a small, cylindrical device typically made of two conductive plates separated by an insulating material, known as a dielectric. When the HVAC system is turned on, the capacitor stores electrical energy. When the motor needs an extra boost to start, the capacitor discharges, providing the necessary power.

How Does an HVAC Capacitor Work?

The basic principle behind an HVAC capacitor's operation is the storage of electrical energy. When the system starts, the capacitor charges, creating an electrical potential difference between its plates. This potential difference is then discharged, providing the motor with the extra voltage it needs to start quickly and efficiently. Capacitors ensure the motor operates at the desired speed, contributing to the system's overall efficiency.

Why Do HVAC Capacitors Fail?

HVAC capacitors, like all electronic components, have a finite lifespan. Several factors can contribute to their failure:

- Age: Over time, capacitors can degrade due to the stresses of constant charging and discharging cycles.

- Overheating: High temperatures can cause the dielectric material to deteriorate, leading to reduced capacitance and eventual failure.

- Voltage Fluctuations: Sudden power surges or voltage fluctuations can overload the capacitor, causing it to fail.

- Poor Quality: Low-quality capacitors or those not suited for the specific HVAC system can fail prematurely.

- Contamination: Dust, dirt, or moisture entering the capacitor can affect its performance and lead to failure.

Can Failure be Prevented?

While HVAC capacitors have a limited lifespan, their longevity can be extended with proper care and maintenance:

- Regular Inspections: HVAC systems should be inspected regularly by professionals who can identify signs of capacitor wear and tear.

- Quality Installation: Ensuring that high-quality capacitors are used during installation can significantly reduce the risk of premature failure.

- Temperature Control: Keeping the HVAC system in a well-ventilated area and maintaining proper airflow can prevent overheating and extend the capacitor’s life.

- Surge Protection: Installing surge protectors can safeguard the system from sudden power surges, preventing overload and capacitor failure.

- Cleanliness: Regular cleaning and maintenance of the HVAC unit can prevent dust, dirt, and moisture from contaminating the capacitor, preserving its efficiency.

- Timely Replacement: Capacitors should be replaced periodically as part of routine HVAC system maintenance, even if they show no visible signs of failure, to prevent unexpected breakdowns.

HVAC capacitors are unsung heroes in the realm of heating, ventilation, and air conditioning. Understanding their function, reasons for failure, and methods of prevention can ensure the smooth and efficient operation of HVAC systems. Regular maintenance, quality components, and a proactive approach to replacements are key to preventing capacitor failure and ensuring the longevity of HVAC systems, ultimately providing comfort and convenience to users.